|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Products

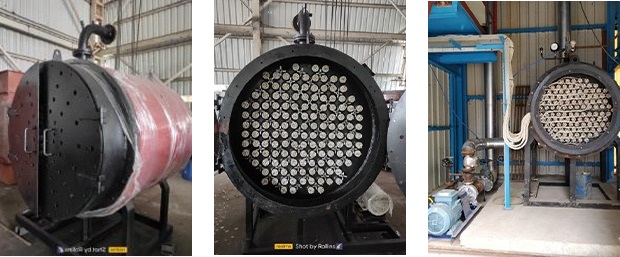

Process Heating > Uni-Therm Electric thermic fluid heater or E-TFH

it is a closed-loop heating system operating at temperatures as high as 340° C. The system comprises a closed-loop circulation of Thermic Oil through user equipment for process heating and the return oil is reheated in the Thermic Fluid Heater. The expansion cum deaerator tank ensures a pressure less and vapor free system. It comes as a packaged skid-mounted unit consisting of the Thermic Fluid Heater along with the accessories such as the Thermic fluid circulating pump and the control panel. The expansion tank is also supplied which can be mounted at an appropriate height to complete the circuit of the heating system.

The Electrical Heaters are arranged in separate sets of equal heating loads with Maximum 120 KW for each Thyristor. Individual selection switches are provided to start only one or all heaters simultaneously depending upon the heating requirement. This ensures soft Start & Stop & avoids sudden Power surges, which increases the Heater & Thermic Oil life. PLC Control available for Higher heating Loads on request. Panel will also have provision for Air conditioner for cooling to control the Heat. Individual MCBs will be provided for a set of 3 Heaters. In the event of any heater getting short, the corresponding MCB shall trip, & the user has to only check that particular set of heaters & set the fault right

The Heaters are of removable cartridge type made of Ni-Cr or Kanthal Wires & Ceramic surface. The heaters are inserted in MS C class tubes for efficient heat transfer & to avoid direct contact with the Thermic Oil. A large surface area is provided to ensure extremely low heat flux. This avoids charring of the Thermic oil & increases its life. A number of Baffles are inserted inside the Shell to provide multiple passes to the Thermic Oil & increase its residence time, ensuring complete heat transfer The safety controls and instrumentation provided ensure completely safe operation and provide Audio Visual Alarm and cuts off the ignition system in case of abnormal operating conditions.

STANDARD CAPACITIES

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||